My New CNC Machine

I've been writing, wrapping up the last of my sculpting projects for a while, and being an overall ruralburbian dad.

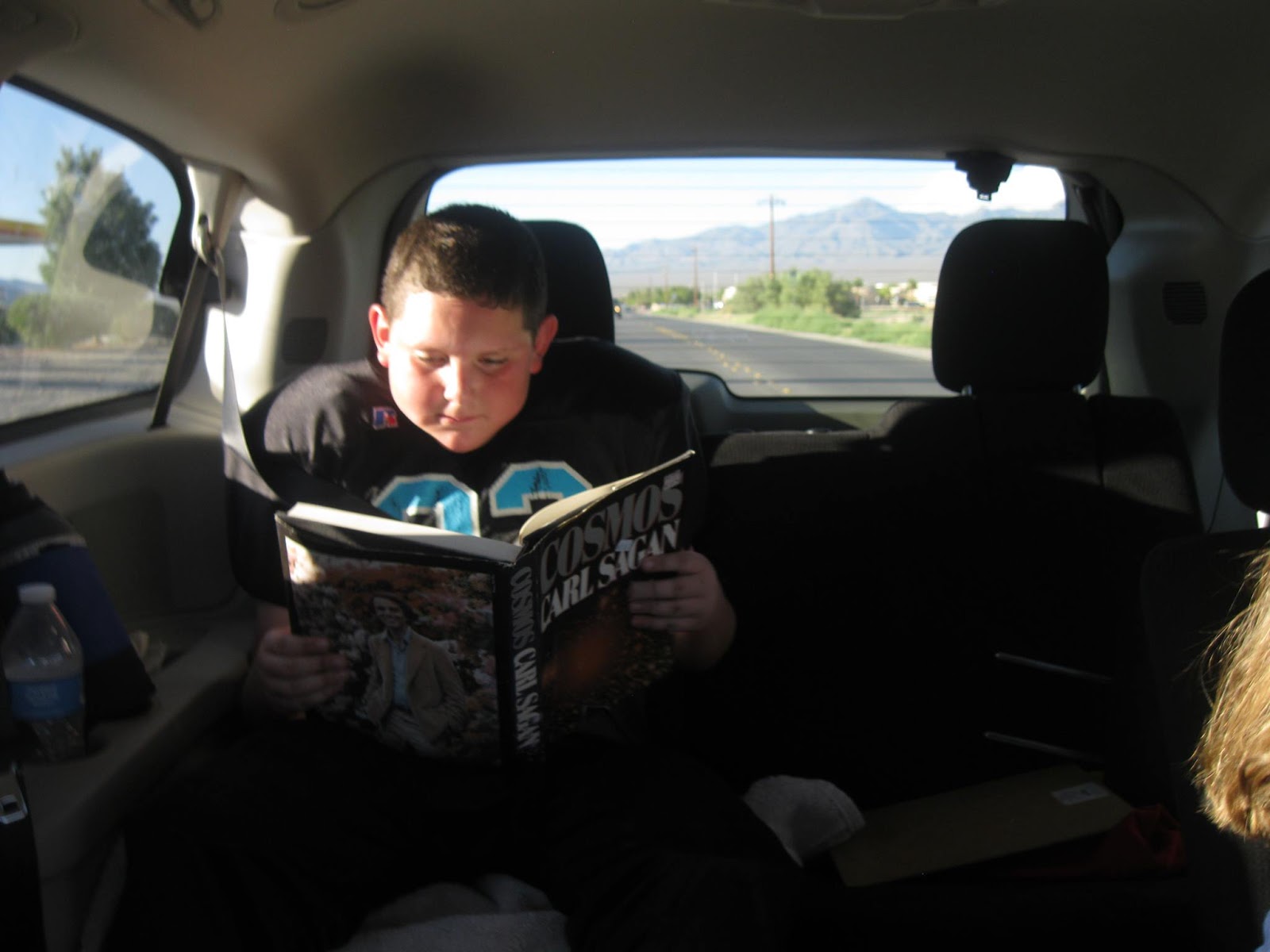

My son, JBR 2, is now 11 years old, and up to my shoulder. He finished his first season in American tackle football, playing defensive line.

I'm very proud of him, along with being on the A/B Honor Roll for school.

On to my new CNC machine.

It's a home-brew job, cobbled together from a hodgepodge of online inspirations and sketches.

I was running into issues with the Z axis when I first assembled it. It kept stalling under its own cantilevered weight. So, I took a lesson from slant-bed lathes, and inclined the whole machine. Much smoother, now.

I call it "lawn-chair style." ;)

Control box is a Deepgroove1 model, with a G540 board and 3 270oz/in Nema 23 steppers.

Spindle is a Hitachi M12VC 2.25 Hp router.

Frame is 15 Series aluminum extrusion, brackets, and t-nut fasteners, all from Faztek, ordered via Amazon Prime. Standard disclaimer: I get a tiny percentage if you purchase through the above Amazon links.

Axes are from John at Microcarve CNC. He makes great little machines, as well as separate axes you can get from time to time on Ebay.

Here's a more conventional look at it. As you can see, it's just a conventional home-built mill, but set up at an angle.

Now I just have to decide on (and save up for) CAM software.

Best,

JBR

Edit to add: Here's my first blog post, about the initial cutting and assembly of the machine.

My son, JBR 2, is now 11 years old, and up to my shoulder. He finished his first season in American tackle football, playing defensive line.

I'm very proud of him, along with being on the A/B Honor Roll for school.

On to my new CNC machine.

It's a home-brew job, cobbled together from a hodgepodge of online inspirations and sketches.

I was running into issues with the Z axis when I first assembled it. It kept stalling under its own cantilevered weight. So, I took a lesson from slant-bed lathes, and inclined the whole machine. Much smoother, now.

I call it "lawn-chair style." ;)

Control box is a Deepgroove1 model, with a G540 board and 3 270oz/in Nema 23 steppers.

Spindle is a Hitachi M12VC 2.25 Hp router.

Frame is 15 Series aluminum extrusion, brackets, and t-nut fasteners, all from Faztek, ordered via Amazon Prime. Standard disclaimer: I get a tiny percentage if you purchase through the above Amazon links.

Axes are from John at Microcarve CNC. He makes great little machines, as well as separate axes you can get from time to time on Ebay.

Here's a more conventional look at it. As you can see, it's just a conventional home-built mill, but set up at an angle.

Now I just have to decide on (and save up for) CAM software.

Best,

JBR

Edit to add: Here's my first blog post, about the initial cutting and assembly of the machine.

Comments