You Can't Stop The Signal Part 2: 3 D Printed Assault Weapons (OH NOEZ!!!)

I like to spend time on gun forums. Probably more than I should. Less than I used to. They're like campfire or bull sessions with folks of like mind, with similar (and not so similar) approaches to the building and use of firearms.

Rarely do the things that happen on gun forums intrude on real life.

Recently, the news networks exploded with much wailing and gnashing of teeth over the fact that someone had used one of those mystifying, voodoo-powered 3d printers to make, of all things, an "Assault Rifle." Oh, the apoplectic verbal feathers that flew over the fact that such a thing could happen.

Article one, from Forbes.

Article two, from Popular Science.

Article three, from HuffPo UK.

Article four, from BoingBoing.

The sky is falling, right? Not quite. Keep reading.

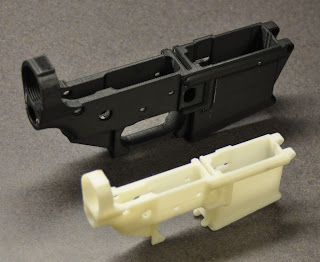

HaveBlue is the name of the intrepid Arfcommer who made this lower receiver on his 3d printer. Remember, in the US, the lower is the part that the government cares about. You are allowed to make your own lower receiver, as long as it's not fully automatic. I explained a lot of this in my first post on the subject, when I put an AR together at my computer desk.

He first tried out the lower with a .22 Long Rifle setup as a pistol.

He then went for the gusto, and converted the pistol to a rifle. Again, entirely legal.

And you know what? It works! Huzzah!

Now, to read some of those comment sections in the articles above, you would think he made the lower receiver out of ground up babies.

Oh, won't someone save us from these evil, unlicensed 3d printers? Puh-leeze.

News flash, folks: Quality 3d printers that can print firearm parts are already out there. They've been out there for years. They usually cost more than a new car, and the truly industrial-class ones cost more than a quarter million dollars (or at least used to).

This is a lot of hullabaloo over nothing. A decent amateur machinist with a desktop CNC mill can make an AR lower stronger, and cheaper, out of aluminum or delrin. The data and know-how has been out there for decades. 2 seconds on Google ("AR lower iges") will give you the information you seek.

Having the data files and the machine isn't enough, though.

You just have to be smart and skilled enough to do something with it. Generally, that precludes your average criminal, who will usually just wait for Eric Holder to mail him one.

The Luddite thinking of those that want to regulate these "evil digital shapes" won't put the genie back in the bottle. If anything, this is a brilliant little milestone in the march towards the next advancement in human technology, and should be celebrated. Kudos to HaveBlue.

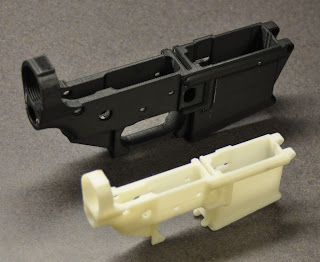

I myself have experimented with the same lower receiver file (available from cncguns.com). Here's a little rework I did to make a simplified single-shot lower receiver. I eliminated the detentes that usually keep the takedown pins in place, and decided to use quick-release pins if I ever wanted to machine this up. Saves on operations. I did this in about 20 minutes. No biggie.

Like I said on my first posting on this subject, you can't stop the signal.

Best,

John Bear Ross

Rarely do the things that happen on gun forums intrude on real life.

Recently, the news networks exploded with much wailing and gnashing of teeth over the fact that someone had used one of those mystifying, voodoo-powered 3d printers to make, of all things, an "Assault Rifle." Oh, the apoplectic verbal feathers that flew over the fact that such a thing could happen.

Article one, from Forbes.

Article two, from Popular Science.

Article three, from HuffPo UK.

Article four, from BoingBoing.

The sky is falling, right? Not quite. Keep reading.

HaveBlue is the name of the intrepid Arfcommer who made this lower receiver on his 3d printer. Remember, in the US, the lower is the part that the government cares about. You are allowed to make your own lower receiver, as long as it's not fully automatic. I explained a lot of this in my first post on the subject, when I put an AR together at my computer desk.

He first tried out the lower with a .22 Long Rifle setup as a pistol.

He then went for the gusto, and converted the pistol to a rifle. Again, entirely legal.

And you know what? It works! Huzzah!

Now, to read some of those comment sections in the articles above, you would think he made the lower receiver out of ground up babies.

Oh, won't someone save us from these evil, unlicensed 3d printers? Puh-leeze.

News flash, folks: Quality 3d printers that can print firearm parts are already out there. They've been out there for years. They usually cost more than a new car, and the truly industrial-class ones cost more than a quarter million dollars (or at least used to).

This is a lot of hullabaloo over nothing. A decent amateur machinist with a desktop CNC mill can make an AR lower stronger, and cheaper, out of aluminum or delrin. The data and know-how has been out there for decades. 2 seconds on Google ("AR lower iges") will give you the information you seek.

Having the data files and the machine isn't enough, though.

You just have to be smart and skilled enough to do something with it. Generally, that precludes your average criminal, who will usually just wait for Eric Holder to mail him one.

The Luddite thinking of those that want to regulate these "evil digital shapes" won't put the genie back in the bottle. If anything, this is a brilliant little milestone in the march towards the next advancement in human technology, and should be celebrated. Kudos to HaveBlue.

I myself have experimented with the same lower receiver file (available from cncguns.com). Here's a little rework I did to make a simplified single-shot lower receiver. I eliminated the detentes that usually keep the takedown pins in place, and decided to use quick-release pins if I ever wanted to machine this up. Saves on operations. I did this in about 20 minutes. No biggie.

Like I said on my first posting on this subject, you can't stop the signal.

Best,

John Bear Ross

Comments

'Now psychopatic killers will be able to 3D print at home their own miniguns, RPGs and tanks'... :o)

Some folks hear the word "gun" and simply shut off their ability to engage in rational discourse with people with other opinions.

It happens.

Best,

JBR

Hey, you're describing my colleagues! My fellow professors, especially in my liberal arts and humanities departments, drive me nuts when they hear stuff like this, or anything dealing with guns or the military.

Anyway, this was a very interesting bit of article. 3D printing is fascinating.

Sorry I'm coming onto the post a bit late. I haven't been reading my blogs lately.

I had planned on doing similar work on my Taig mill, but was going to turn the spindle 90 degrees and lower it as close to the table as possible for rigidity. Glad to see others doing gunsmith work on these small machines. If you ever post to one of the big gunsmithing forums (Like Practical Machinist), they will tell you that nothing but a 2000 pound Bridgeport mill and a similar sized lathe will produce acceptable work. Seems every hobby pursuit has its "tool snobs". Happy machining to you!