A Primer On 3D Production, Part Four

This is a primer for folks thinking that digital sculpting and rapid prototyping will magically solve their problems when it comes to making their own miniatures company.

Bottom line is: it won't. I've stepped on a few land mines in the past and can show you one particular path that won't result in severed limbs and a broken career. Mostly.

This is part four, mass production and molding (or "moulding" for you UK types). There are two major categories of molding: rubber molds, and metal molds. One is usually formed around an existing master, the other is a hollow space machined into blocks of material.

Injection molding, like the styrene model kits you find at hobby stores, is a whole level of madness unto itself. Mark Mondragon, with his stunning success with the reformed Wargames Factory, the gents who run BrickArms, or the blokes over at Renendra could all address that subject far better than I.

Here's a neat little guide to "guerilla CNC machining," if you're insane enough (like me) to try and do it on your own. I'm at the very start of the learning curve, but hope to make progress someday.

If you're a little guy, just starting out, I would advise you that it's better to start in rubber molds and spincasting, and build your business empire from there.

Injection molds cost tens of thousands of dollars. Rapid prototypes and rubber molding is in the high hundreds, low thousands, at least starting out.

Injection molds cost tens of thousands of dollars. Rapid prototypes and rubber molding is in the high hundreds, low thousands, at least starting out.

So, on we go.

There's a reason, beyond it's "just what you do," why manual sculptors use two-part epoxy putties (green stuff, brown stuff, ProCreate, Magic Sculpt, etc.) and metal parts in their master models.

The original sculpting putties were made to be plumbers putties, with construction and other hard-environment uses as the purpose for their formulation. They're tough and flexible, and can take a moderate amount of heat and pressure.

I often heard Reaper talk about "greens," as completed hand sculpts are known, needing to

withstand 300 degrees fahrenheit and crushing pressure for mastering or production molding (you're basically

forming a tire around your sculpts).

To do that to the older wax or plastic rapid-prototyped masters would have just resulted in boiling smears and puddles.

Photopolymers and resins melt quickly, and snap under the slightest pressure. That's changed.

I'm not a caster, leaving that arcane art to those that do it far better than I, but I know that the new Nicem Green rubbers ( http://www.contenti.com/products/spin-casting/179-389.html ) are able to vulcanize at lower heat, without destroying the fragile master (which, again, isn't so fragile anymore).

Both of the previously-mentioned service bureaus in other blog posts (Moddler and VisionProto), or more specifically, their Perfactory machines, can now produce high resolution prints in materials that can take up to 280 degrees fahrenheit.

This enables you to skip the process of "translating" the master to something that can withstand high-temp vulcanizing. During the Reaper CAV days, we used to lost-wax the masters into silver, and these became the production masters. Here's an old page of how it used to be...

Detail gets lost, casting flaws have to

be corrected, and your final product is another generation away from

the highly detailed vision you started with. The new materials

combined with the new rubbers lets you go straight to production

molding, if you're going to do small runs. Your caster should make this call, though, since they are the experts in this regard.

---------------------------

---------------------------

As you may of may not know, most small

companies in the miniatures business don't do their own casting.

Most of it funnels through a handful of contract casting houses that

also put out their own products. I mean, do you want to sling molten metal, or develop resin allergies? The metal part is fun (I got to run the spincasters once at Reaper), but I dislike potential chemical reactions. Best left to the pros, either way.

Reaper, BTW, contract casts, and has helped many small companies (and some large ones) fulfill their production needs.

-----------------------------

As far as what material to cast in, that's a mixed bag.

Resin can be used in large model parts, or in those requiring intricate levels of detail, but any mistakes or miscasts are usually lost to the trash pile. Molding is easier to make, usually, but wears out faster.

Pewter/white metal parts can be cranked out cheaper, but are harder to mold, usually. Any screwed up parts can be thrown back into the melting pot, though.

Both materials are subject to commodities fluctuations. Tin and lead move up and down on the metals market. Most resins are petroleum derivatives, and ride the OPEC roller coaster. It's maddening.

-------------------------

Alright, story time.

Like picking a sculptor, picking the

right caster is a crucial choice.

I'll illustrate with an example from my

own past.

When I had the license from Reaper

(Thansk Ed!) to produce 1/60th scale CAVs, I went with the

recommendation of Nick Tompkins from Epicast, who lived in Vegas at

the time. Great guy, Nick Tompkins.

Nick told me of a guy in named Dave,

with whom he had worked with in the past when he was part of

Armorcast.

I contacted Dave via telephone, worked out the terms so that both parties were happy, and hired him for the Dictator and Despot kits (a large mech and tank, respectively).

Great castings, parts were sorted ahead of time, and he was a dream to deal with.

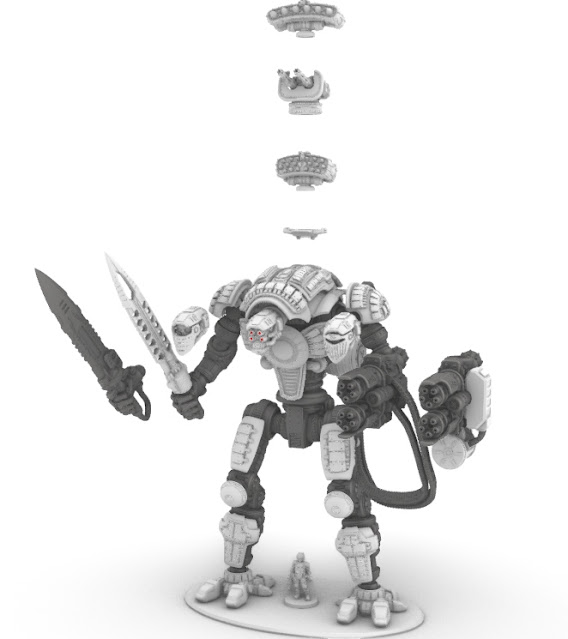

A layout of the kit by Inso, I believe. Notice the pale areas he had to fill in to repair it.

I then did my third kit, the 1/60th scale Scorpion, using a caster I met off a forum. I figured, why

not, his stuff looked legit, he said he did major works for museums,

and took a shot on him.

It was a disaster. The resin was

runny and stank, there were mold lines through the worst

possible places, and he dropped out of sight with my rapid-prototyped

master model.

I ended up selling the lot as "Factory

Seconds" (my catchy marketing phrase for "junk"), and curled up in a ball for a

few years. It was the end of retailing, for me, and I focused instead on just sculpting. Maybe he did me a favor, I don't know.

-------------------

So, sad sad story aside, when contract casting, make sure you

realize it's just as important a choice as picking the right

sculptor, or the right target audience.

You can have the most

brilliant product in the world, but if you can't reproduce it

yourself, make sure you pick competent, experienced people. Ask for past work. This is

not amateur hour, and if the price is stiff, consider the amount of work it takes. You usually get what you pay for.

So, that's my screed. I hope this

helps. If you have any questions, feel free to ask in the comments.

Best,

JBR

Comments

My brain is fried from too much caffeine and sculpting all day.

;)

Best,

JBR

I found silicone rubber spin moulds too prone to ripping and produced much fewer useable metal masters than an organic rubber mould.

The prints were destroyed in the silicone moulds anyway so this way I keep the prints as a back up. I did try a rc31 print in a black rubber mould and it moulded fine, though I'd be worried about fragile parts breaking before the moulding is complete.

I know Hasslefree also did resin transitional masters for the Grymn weapons I just did, a hard-learned lesson from the CAD guns I originally sold them in 2006.

I am sure the high-temp resin is much easier to work with than lost-waxing molten silver.

Thanks for the contribution, I appreciate it.

Best,

JBR

rubber molding

Thanks