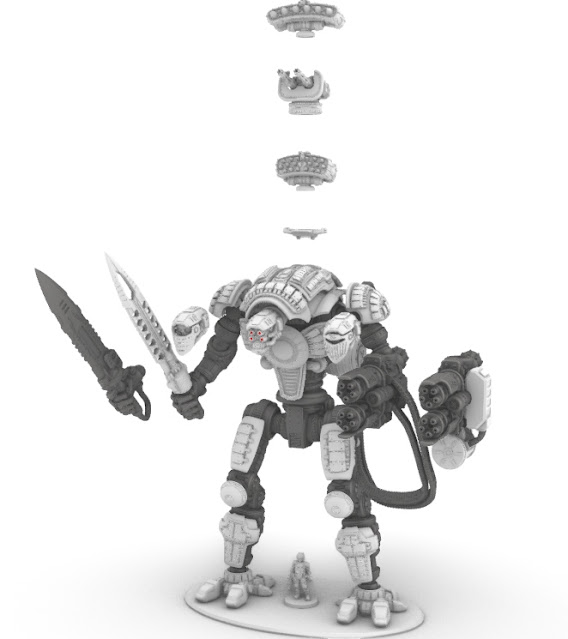

Project Maggie Express .STL Files

As a show of appreciation, I have worked up a new Frame and Armor Package for Project Maggie, streamlining the wide parts array to a few of the main favorites. These new files will be prefaced with the "PM-NF24" headliner, for Project Maggie-New Frame 2024. New armor packages, new head, new download-friendly-sized parts, all clean and pre-supported. Don't worry, if you have a previous Maggie Conversion kits, the deluge of parts is still there, if you have the old files. The price is now going up on that package, but you are still locked in at the old price with access to the new files. In the meantime, I am offering an Express package of the self-contained new upgrades, if you don't want to fiddle with all the extra options (there's a lot; it's what I do ;) ). A Project Styx upgrade is coming, as well with a new sensor head, power cables, and shoulder armors, or you can substitute the new Maggie parts. If you've never put together one of